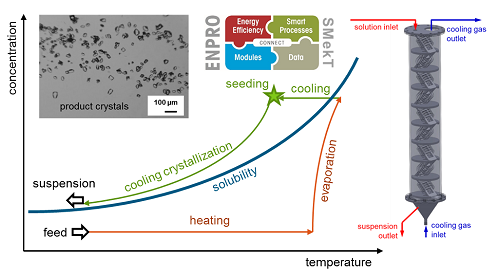

ENPRO: SMekT

Energy efficiency and process acceleration for the chemical industry -

Smart Mini-Plants for the development of efficient continuous separation processes

In the ENPRO-SMekT joint project, continuous processing methods are being developed to produce special products on a mini-plant scale. In addition to apparatus development and demonstration for evaporation, continuous crystallization, and continuous solid/liquid separation with crystal washing, the focus is also on developing non-invasive measurement technology. The energy and resource requirements of innovative continuous separation processes are quantified with the aid of novel tools.

Information on the project

| Contact | Prof. Dr. Norbert Kockmann |

| Professorship | Laboratory of Equipment Design (AD/BCI) |

| Funding | Bundesministerium für Wirtschaft und Energie (BMWi), Projektträger Jülich (PTJ) |

| Partner | TU Dortmund, Lehrstuhl für Anlagen- und Prozesstechnik (APT); Karlsruher Institut für Technologie (KIT), Institut für Mechanische Verfahrenstechnik und Mechanik (MVM); Karlsruhe Evonik Industries AG, Hanau HiTec Zang GmbH; Herzogenrath SONOTEC Ultraschallsensorik Halle GmbH, Halle/Saale |

| Term | from 01.07.2014 |