For the twelfth time AD has been awarded with 10 stars from the BCI student association

2012 - 2013 - 2014 - 2015 - 2016 - 2017 - 2018 - 2019 - 2020 - 2021 - 2022 - 2023

Laboratory of Equipment Design

Welcome to the laboratory of Equipment Design, established in April 2011 under the direction of Prof. Dr.-Ing. Norbert Kockmann.

Picture of Month

April 2024

Liquid-liquid separation experiments in zero gravity at ZARM in Bremen

March 2024

Kickoff meeting of ENPRO REUNION at TU Darmstadt

February 2024

Poster show of the Project work: Introduction to process engineering (PeP)

January 2024

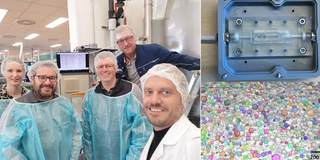

iSPS project meeting in Münster am Lech – measuring industrial emulsions

News

Interview with former employee Dr.-Ing Aljoscha Frede

Spotlight Forschung: Dr. Aljoscha Frede zu zertifizierten Fortbildungen während der Promotionsphase

AD welcomes Mathias Schmitz as research associate

Mathias Schmitz studied chemical engineering at TU Dortmund University and joined the team of the Laboratory as a PhD student on 01.08.2023.

AD welcomes Laura Marsollek as research associate

Laura Marsollek studied biochemical engineering at TU Dortmund University and joined the team of the Laboratory as a PhD student on 01.07.2023.

Nadine Niesert with sunrise over Dortmund in the tv newscast "Lokalzeit"

Nadine Niesert enjoyed a beautiful view of the sunrise over Dortmund from her office on the 5th floor in the early morning of 02.03.2023.